Hardwood Window Frames: Strength, Longevity, and Sustainability

- 22 December 2025|

- News

Few building materials are as sought-after as timber, and hardwood window frames remain a preferred solution for architects, developers, and housebuilders who prioritise strength, durability, and longevity.

This article examines why hardwood continues to outperform many alternatives, exploring its structural properties, resistance to weathering, and sustainability credentials. We’ll also compare hardwood with other window materials to help you make informed specifications.

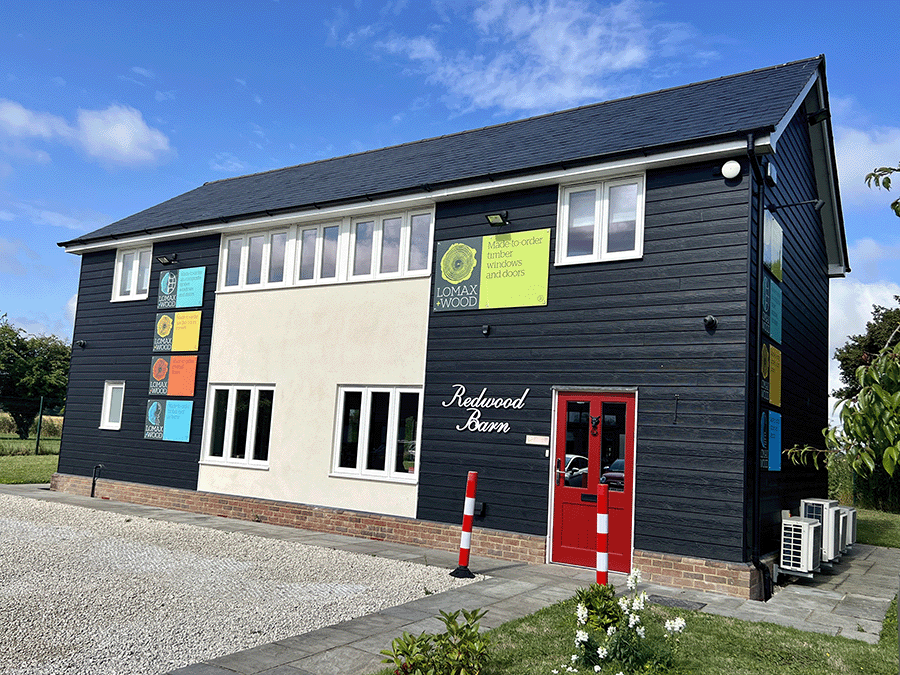

As providers of made-to-order timber windows and doors, at Lomax + Wood we have decades of experience in knowing what makes timber so special.

Why hardwood window frames deliver superior performance

Hardwood species such as Oak, Sapele, and engineered hardwood offer exceptional structural integrity. Unlike other materials, hardwood provides superior stability, meaning frames maintain their shape and function across a wide range of temperatures and moisture levels.

Key benefits include:

- Higher density – hardwood species typically range from 600-900 kg/m³, providing greater strength than softwood (400-550 kg/m³) and better resistance to impact and forced entry

- Natural durability – inherent resistance to rot, fungal decay, and insect attack

- Excellent insulation properties – wood’s cellular structure reduces heat transfer and contributing to improved energy efficiency

- Minimal expansion and contraction – engineered hardwood in particular offers excellent stability, reducing the risk of gaps, leaks, or operational issues

These characteristics make hardwood window frames particularly suitable for exposed locations, conservation areas, and projects where longevity and low maintenance are critical specifications.

Hardwood vs other window materials: a direct comparison

Hardwood vs aluminium

Aluminium frames offer strength and low maintenance but have drawbacks in thermal performance. Aluminium’s high thermal conductivity means it transfers heat rapidly, leading to cold air infiltration and potential condensation issues without proper thermal breaks.

Hardwood provides natural insulation, helping to reduce heat loss and lower energy bills. While aluminium frames resist corrosion, they lack the aesthetic warmth and character that timber brings to both heritage and contemporary projects.

Hardwood vs uPVC

Vinyl windows and UPVC windows are marketed as low maintenance alternatives with a lower initial cost. However, uPVC window frames have several disadvantages:

- Limited lifespan – typically 20-25 years before discolouration or brittleness occurs

- Poor repairability – damage often requires full replacement rather than localised repair

- Less robust in extreme weather – can become brittle in cold conditions or warp in high heat

- Environmental concerns – PVC production involves chemicals and the frames are difficult to recycle

Hardwood windows, by contrast, can be repaired, refinished, and maintained indefinitely. With proper sealing and maintenance requirements met, hardwood frames deliver far better long-term value than vinyl frames.

Hardwood window frames: durability and weather resistance

One of the most significant advantages of hardwood window frames is their proven resistance to the UK’s variable climate. Modern hardwood windows incorporate factory-applied finishes, advanced weather seals, and internal glazing to prevent water damage and ensure long-term performance.

Weather testing results for Lomax + Wood hardwood windows:

- Air permeability: Class 4 (highest standard)

- Wind resistance: Up to Class CE2400/C5 depending on product

- Water tightness: Class 9A/7A – exceeding requirements for exposed locations

These test results demonstrate that properly manufactured hardwood frames perform exceptionally well, even in extreme weather conditions. With appropriate maintenance – typically a fresh coat of paint or stain every 5-8 years – hardwood windows resist rot, moisture ingress, and structural degradation.

Energy efficiency and thermal performance

Hardwood’s natural insulating properties contribute directly to a home’s energy efficiency.

When combined with high-performance double glazing, hardwood window frames help minimise heat loss and reduce heating costs. At Lomax + Wood, our hardwood casement windows achieve U-values as low as 1.0 W/m²K with optional upgrades, while our hardwood sash windows reach 1.1 W/m²K, both exceeding current Building Regulations requirements.

For homeowners and commercial clients, this translates to:

- Lower energy bills throughout the building’s lifecycle

- Improved comfort with reduced cold air infiltration

- Better acoustic insulation (up to 42dB with acoustic glazing options)

Sustainability: full Chain of Custody certification

Environmental responsibility is increasingly important for architects and developers specifying materials for modern projects. Hardwood’s sustainability credentials depend entirely on responsible sourcing.

At Lomax + Wood, environmental responsibility is central to our manufacturing philosophy. We source all timber used in our bespoke windows and doors with full Chain of Custody certification (FSC® or PEFC), ensuring complete traceability throughout the entire supply chain, from the forest to the finished product.

Unlike other sustainability credentials, this certification provides verified proof that timber originates from responsibly managed forests. For projects pursuing BREEAM, Home Quality Mark, or other environmental standards, this documentation is essential.

Security and structural performance

The inherent strength of hardwood makes it an excellent choice for security-conscious projects. Lomax + Wood hardwood windows are tested to PAS 24:2016 and comply with Part Q of the Building Regulations, providing verified protection against forced entry.

The density and strength of hardwood allows for:

- Secure fixing of multi-point locking systems

- Resistance to crowbar attacks and impact

- Stability that maintains lock engagement over decades

This combination of strength and proper maintenance makes hardwood windows significantly more secure than uPVC or vinyl windows, which can be more easily compromised due to their lower structural integrity.

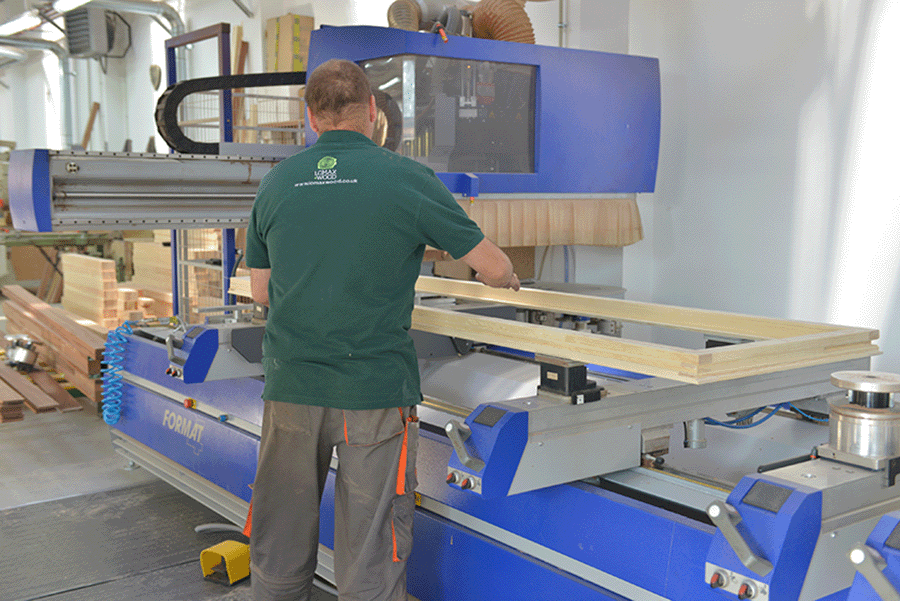

Lomax + Wood’s hardwood window range

At Lomax + Wood we manufacture a range of hardwood windows designed for both heritage and contemporary projects. Our product range includes:

Made-to-order timber casement windows with U-values as low as 1.0 W/m²K, weather tested to the highest standards, and available in various hardwood species including Oak and Sapele.

Traditional sliding sash windows combining period aesthetics with modern performance. Internally glazed, fully weather-stripped, and achieving U-values as low as 1.1 W/m²K.

An economical alternative to traditional box sash, featuring spring-balanced operation, factory double glazing, and PAS 24 security certification.

All windows are made using responsibly sourced FSC® or PEFC certified timber including Engineered Redwood, Hardwood, Oak or Accoya, with custom sizing and various colour finishes available. Each product is made to order, allowing us to meet specific architectural requirements while incorporating practical features such as secure locking systems, durable finishes, and appropriate glazing options to improve comfort and efficiency.

Is hardwood the right material for your project?

Hardwood window frames represent the best choice for projects where durability, aesthetic quality, and long-term performance are priorities. While the initial cost may be higher than vinyl or UPVC alternatives, the extended lifespan, superior thermal performance, and maintenance advantages deliver significantly better value over the building’s lifecycle.

For architects and developers working on premium residential developments, listed buildings, conservation areas, or commercial projects requiring proven performance, hardwood windows offer unmatched functionality and timeless appeal.

Get expert specification support from Lomax + Wood

Choosing the right window specification requires detailed knowledge of performance characteristics, regulatory requirements, and site-specific conditions. Our technical team works closely with architects, developers, and housebuilders across the UK to specify timber windows that meet exact project requirements.

Whether you’re restoring a heritage property, developing a new residential scheme, or specifying windows for a commercial project, Lomax + Wood provides comprehensive support from initial design through to installation.

Contact us today for a free consultation and quotation. Complete our online contact form or call us on 01277 353857.