Sash Window Dimensions: A Practical Guide for Architects and Developers

- 22 December 2025|

- News

Specifying timber sash windows for heritage or new build projects requires precise dimensions to ensure authentic proportions, performance, and proper installation.

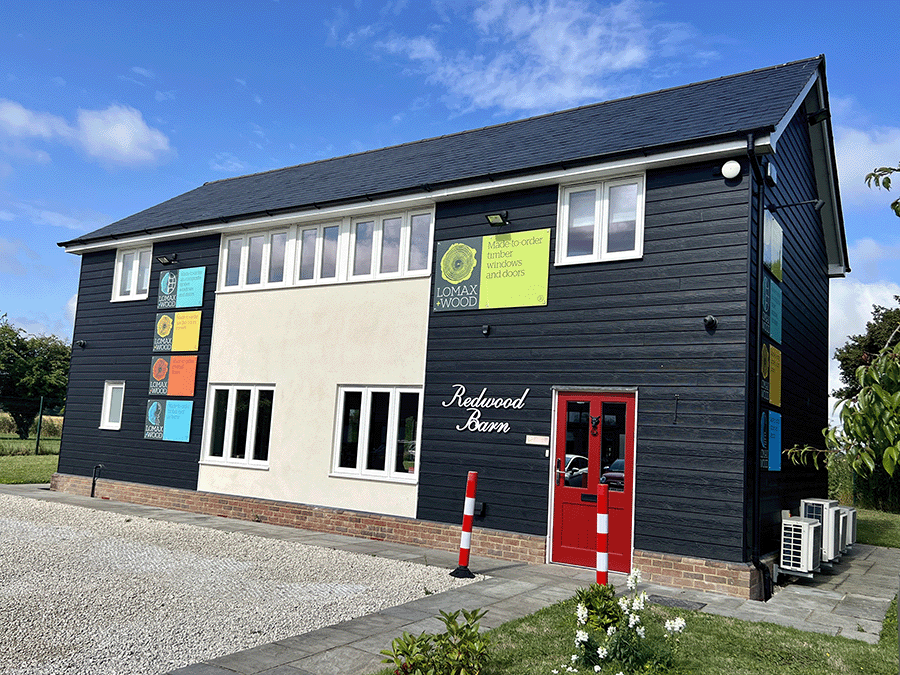

At Lomax + Wood, we provide bespoke made-to-measure timber windows and doors. With decades of expertise behind us, we are perfectly placed to help you find the perfect sash window dimensions for your project.

This practical guide covers what architects, developers, and housebuilders need to know about sash window dimensions, whether you’re working on period properties, conservation areas, or contemporary developments.

The enduring appeal of timber sash windows

Timber sash windows continue to be the most popular style of window for both heritage and new build projects across the UK. Their enduring appeal isn’t purely aesthetic—although the vertical sliding design and elegant proportions certainly contribute to their status in period properties.

Key advantages include:

- Authentic appearance: Essential for conservation areas and listed buildings where planning restrictions apply

- Energy efficiency: Modern timber sash windows achieve U-values as low as 1.1 W/m²K, significantly better than original single-glazed designs

- Durability: Properly maintained timber windows can last 60+ years, far exceeding the lifespan of upvc windows

- Design flexibility: Available in different configurations and styles, from Georgian sash windows through to contemporary interpretations

Unlike uPVC sash windows, timber allows for historically accurate detailing—slim sightlines, putty glazing, and true period proportions that conservation officers demand.

Understanding sash window dimensions and sizing

Standard window sizes vs made-to-measure

While uPVC window sizes are typically manufactured in standard configurations, timber windows offer greater specification flexibility.

Sash windows (like those we offer at Lomax + Wood) can be made in almost any size or with any dimensions.

This is particularly important when working with historical buildings. Original openings rarely conform to modern dimensions, particularly in buildings from the Georgian and Edwardian periods where masonry openings varied significantly.

What to measure and why it matters

When surveying for sash window dimensions, measure:

- Structural opening width and height (brick-to-brick)

- Depth of reveal (affects frame depth and internal finish)

- Head height (determines top sash proportions)

- Sill projection (influences drainage and weathering)

For bay window configurations, each face requires individual measurement—don’t assume symmetry in older properties.

Getting the proportions right

When specifying sash windows for historic properties, it’s important to recognise Georgian and Victorian proportions.

Authentic sash window designs follow classical proportions:

- Traditional six-over-six arrangements typically use a 1:1.6 (width:height) ratio

- The top sash is usually slightly shorter than the bottom to accommodate the meeting rail when closed

- Glazing bar widths should be proportionate—typically 20mm for standard installations

These ratios, while not essential, help to achieve period-correct aesthetics, particularly in conservation areas where planning officers scrutinise window designs closely.

Accommodating modern glazing

Modern double units are substantially thicker than historic single-pane glass, requiring deeper frame rebates and adding significant weight that demands upgraded balance mechanisms.

Spring balanced sash windows often provide a more practical solution than traditional cord-and-weight systems when accommodating these contemporary glazing specifications.

Heritage projects: listed buildings and conservation areas

When working on listed buildings or within conservation areas, accuracy becomes non-negotiable. Planning authorities and conservation officers expect like-for-like replacement that respects original proportions.

Single-glazed sash windows remain the only acceptable solution for many listed properties. While these don’t meet current Building Regulations for thermal performance, they’re often mandated by English Heritage guidelines.

For conservation work, you may need:

- Putty glazing (not modern gaskets)

- Authentic glazing bar profiles and widths

- Period-appropriate hardware

- Exact replication of existing dimensions and detailing

Why historic buildings need special attention

Historic buildings present unique challenges:

- Openings are frequently out-of-square

- Wall thicknesses vary

- Subsidence or settlement may have altered original dimensions

- Each window often differs slightly, even within the same elevation

Made-to-measure manufacturing is essential. Standard double configurations won’t suffice when every opening has unique dimensions.

Lomax + Wood’s range of wooden sash windows

We manufacture three distinct sash window ranges, each designed for specific applications and performance requirements:

Our most traditional offering, featuring:

- Concealed weights and pulleys for authentic operation

- U-values from 1.3 W/m²K standard (1.1 W/m²K upgraded)

- Acoustic insulation from 36dB standard up to 42dB (Acoustic+)

- PAS 24:2016 security certification

- Available in dimensions from 1024mm × 511mm to 1250mm × 1600mm

Box sash designs suit heritage projects where traditional operation is specified, and where sufficient reveal depth exists to accommodate the box mechanism

The most versatile window style for contemporary projects and new builds:

- More economical than traditional box sash construction

- Ideal where flush reveals have been detailed

- Factory double-glazed as standard (4/16/4 toughened/toughened low-e argon)

- 3 W/m²K U-value as standard

- Internally glazed for improved security

- Dimensions from 1024mm × 511mm to 1024mm × 1250mm

Spring balanced mechanisms eliminate the need for deep reveals, making them perfect fit solutions for modern construction where wall thicknesses are reduced.

Specifically for listed buildings and conservation areas:

- Putty glazed with traditional detailing

- True glazing bars (not applied)

- Compatible with vacuum-sealed units for improved performance

- Made-to-order to match existing specifications exactly

While these don’t meet current Building Regulations for new installations, they’re often the only compliant option for heritage work.

Our single glazed windows can also come with vacuum-sealed units to offer a compromise and provide improved thermal performance.

Our vacuum-sealed options include Fineo 6, Fineo 8, and Fineo 10 units, varying between 6.7mm to 9.7mm in thickness and offering a U-value as low as 0.7 W/m²K (glass only).

What’s the difference between box sash and spring balanced sash windows?

Box sash windows use traditional weights and pulleys concealed in a box frame – this is a more historically accurate design. Spring balanced windows use spiral balances, require less depth, and are more economical—ideal for new builds with flush reveals.

How made-to-order manufacturing works for your project

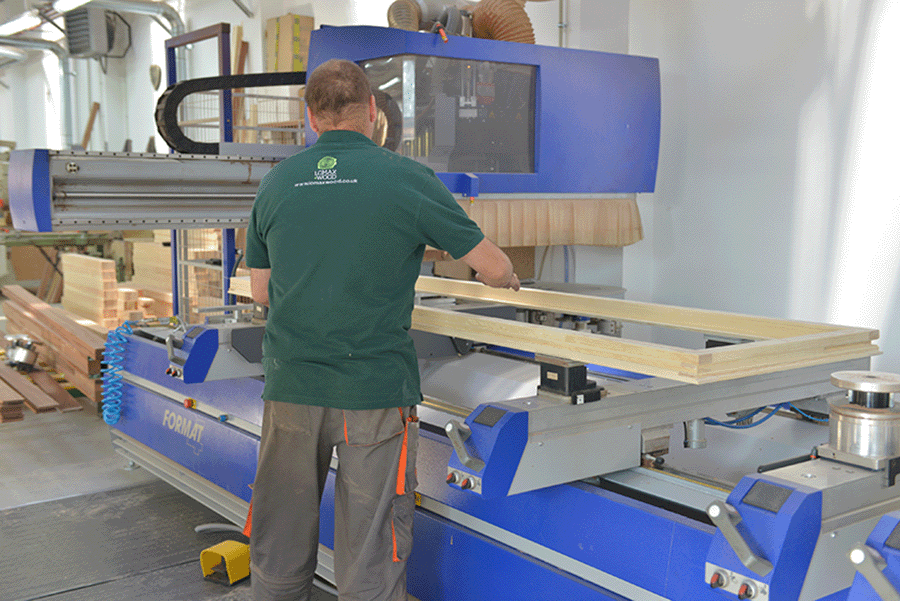

Unlike mass-produced uPVC window sizes, every Lomax + Wood sash window is manufactured to order.

Made-to-measure manufacturing means:

- Every window fits the surveyed opening precisely

- No on-site modification required

- Historically accurate proportions maintained

- Integration with unusual architectural details

Timber species and finish options

All windows are made using responsibly sourced FSC® or PEFC certified timber including Engineered Redwood, Hardwood, Oak or Accoya, with custom sizing and various colour finishes available. Each product is made to order, allowing us to meet specific architectural requirements while incorporating practical features such as secure locking systems, durable finishes, and appropriate glazing options to improve comfort and efficiency.

Available timber specifications include:

- Engineered European Redwood with hardwood cill (standard)

- Hardwood Sapele

- Engineered Larch

- Engineered Oak

- Accoya (for extreme exposure or coastal locations)

Finish options extend beyond standard RAL 9010 white to any RAL colour, stained finishes, or dual colours (different internal and external finishes).

Get your sash window specification right: contact Lomax + Wood

Whether you’re restoring a Georgian terrace in a conservation area, developing a new build estate that requires authentic detailing, or retrofitting modern performance into period properties, we can help.

At Lomax + Wood, we manufacture made-to-order timber sash windows that meet exact specifications—no compromise on dimensions, performance, or aesthetics.

Contact our team for technical specification support and a free, no-obligation quote. Complete our contact form or call us on 01277 353857.